All pictures are thumbnails. Click on them for a larger version.

Decrease moment of inertia

Small diameter, light clutches have a lower moment of inertia than large, heavy clutches. It takes less power to accelerate a low moment of inertia object. Tie a tennis ball to a three foot piece of rope and spin it around over your head. Then do the same thing with a bowling ball. Which is easier to accelerate?

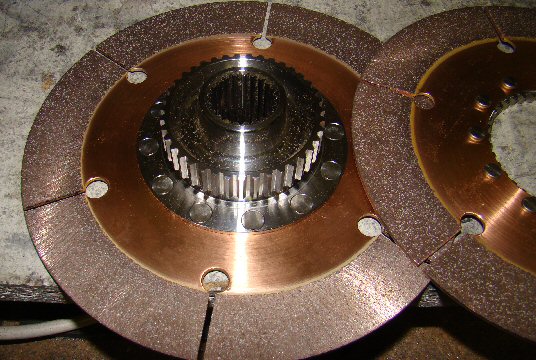

Old clutch new clutch

This shot compares the factory clutch to the 7 1/4", triple disk clutch from PowerTrain Technology. Clutch wizard Steve Fox came up with a design that will hold all the torque my engine will ever make, yet can be slipped for smooth starts on the street. The custom, CNC'ed flywheel came from Jetstream Motorsport in England.

Gear drive disks

The Noble transaxle input shaft is very short, which meant that I could not use a normal 3-disk setup where each disk is mounted to its own hub that is splined to the input shaft. QuarterMaster makes this trick hub arrangement in which there is only one hub splined to the input shaft. The other two disks are splined to the main disk hub. This arrangement provides more than enough spline engagement.

Gear drive disk hub

Close-up of the main hub showing inner and outer splines. Unfortunately, the QuarterMaster disks were too aggressive for street driving. Engagement was close to toggle switch, and any attempt at slipping resulted in embarrassing chatter. Steve Fox of PowerTrain Tech attached his friction material to the QuarterMaster hubs, and now everything is right in the world.

Old master new master

The 7 1/4" pressure plate requires much less release bearing travel than the factory clutch. Noble uses a Girling 3/4" master cylinder, so all I had to due was replace it with a 5/8" part from Pegasus Auto Racing Supplies.

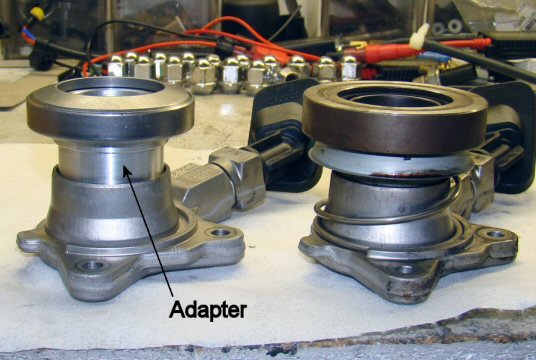

New slave old slave

Steve Fox from PowerTrain Tech was adamant that I use a tapered release bearing with his 7 1/4" pressure plate. That meant some custom fab that would be way beyond my capabilities and equipment. Whenever I reach a roadblock like this, I turn to Craig Hill of Top of the Hill Performance Center. Craig and his shop have the experience and the equipment to make just about anything, and the drive to make it right.

Custom slave adapter

The Noble slave cylinder and release bearing is on the right, the PowerTrain Tech release bearing and Craig Hill's adapter is on the left. The slave cylinder is a factory Ford part. Craig designed and machined the adapter that mounts the PowerTrain Tech release bearing to the Ford slave. I have thousands of trouble-free miles on this setup.

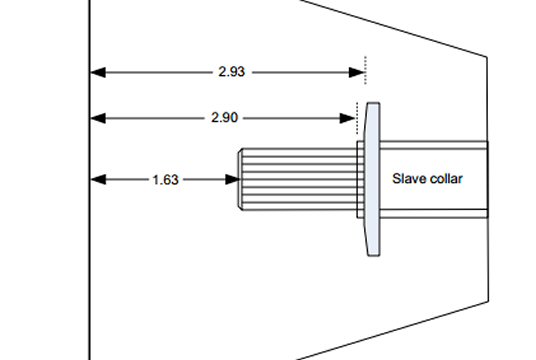

Geometry Problem!

The road to a triple disk Noble clutch was rocky in spots. The transaxle input shaft is very short. I spent a few hours making measurements and transferring them to a Visio diagram so I could explain the issue in detail to suppliers. The solution is the QuarterMaster "geared hub" with PowerTrain Technology friction material, pressure plate, and release bearing.

Bench bleed new master

This is just a tip for guys having clutch release problems. You can bleed the lines and the slave all day, but an air bubble in the master means that the clutch is not gonna disengage. The solution is bench bleeding the master cylinder as shown above. Pump the pedal while a helper watches for bubbles in the reservoir. No more bubbles means you are done.